The EMERWALL operational team is made up of three young engineers, Valentin, Louis and Quentin, each specialising in new energies with a focus on insulating materials, mechanical engineering specialising in industrialisation and renewable energies.

The output of sugar cane factories is increasing as production lines are modernised, as is the quantity of sugar cane bagasse (fibrous residue).

Unfortunately, there is a great deal of agricultural waste, which is either not recycled at all or has very little added value. The storage and treatment of this waste also represents a major financial burden for producers.

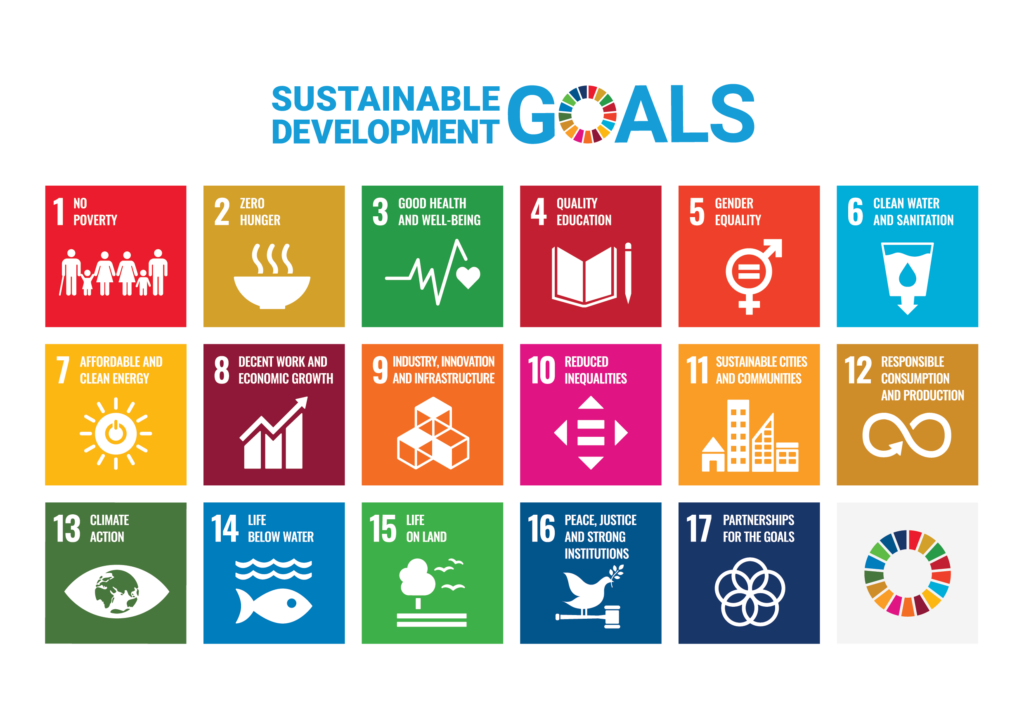

The construction and renovation markets are expanding. This trend has been amplified by the recovery triggered by the pandemic and national policies in favour of the ecological transition and sustainable development.

At the same time, most building materials are imported. They are expensive to buy and their performance is not optimised for local climatic conditions.

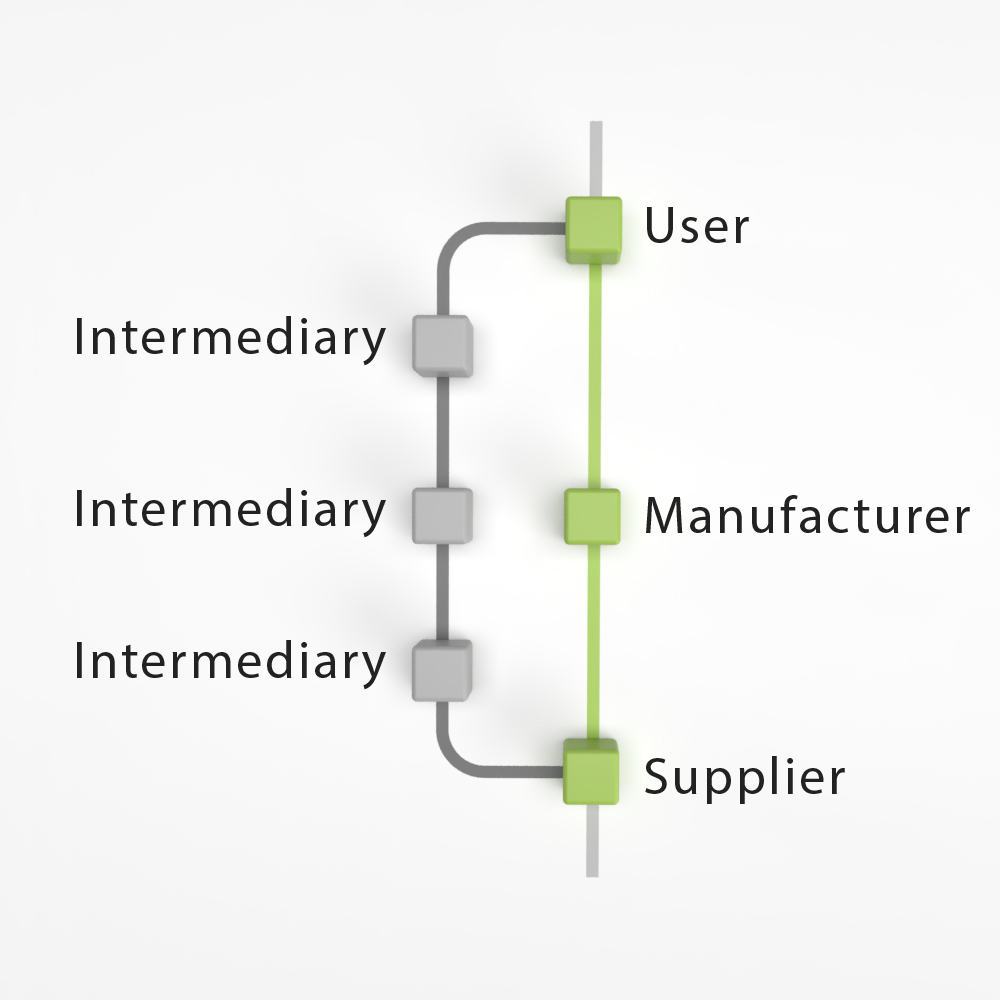

The idea was born out of these two observations, and we set about developing a local agricultural by-product to create an eco-responsible, high-performance solution that perfectly meets the needs of construction markets in tropical environments: to manufacture effective biosourced insulation panels for construction, made from over 90% sugarcane bagasse sourced exclusively from Martinique distilleries, for the Caribbean and Latin American markets.

The performance of the eco-responsible solution we’ve developed, the value chain we’ve put in place and our mastery of the supply chain mean that we can now extend the scope of our operations beyond the tropics.

Turning an agricultural by-product into an affordable, certified bio-sourced insulating material

Managing the flow of bagasse required for production

Innovating with new production methods

Offer high-quality bagasse to explore new markets

To produce is to destroy! Favour an energy self-sufficient process